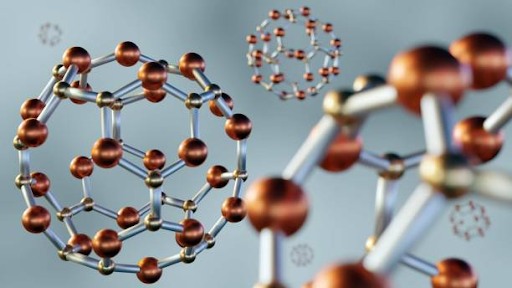

Exploring Zeolite Molecular Sieve: Unique Properties and Industrial Applications

Zeolite molecular sieves are widely used in many industries due to their excellent adsorption characteristics. They are widely used in various processes including gas purification and chemical production as a type of adsorbent solution. This article focuses on the characteristics of zeolite molecular sieves and the versatility of their use in various industries.

Zeolite Molecular Sieve

A zeolite molecular sieve is a crystalline silicate containing aluminum, silicon, and oxygen that has a three-dimensional pore structure. These pores are of uniform size and hence, zeolite molecular sieves are ideal for the selective adsorption of molecules. This selectivity makes them an invaluable component in many adsorbent solutions that are intended for certain industrial applications.

Properties

Zeolite molecular sieves are well known for their ability to selectively absorb water, gasses and other molecules by size. This is because their pore structure is regular and can be easily manipulated during the synthesis process. Also, zeolite molecular sieves are thermally stable and can work under high temperature and pressure which is suitable for industrial processes.

Industrial Uses

The use of zeolite molecular sieves is diverse and they are applied in various industries. In the petrochemical industry, they are used in the process of refining and purification of hydrocarbons. Some of the uses of activated carbon in environmental industries are in the purification of air and water, for example in the treatment of industrial wastes. Besides, they are used in the generation of oxygen-rich air in medical and industrial applications through adsorptive air separation.

Progress

Constant innovation has seen the improvement of the performance and effectiveness of zeolite molecular sieves. The adsorbent solutions suppliers are always trying to develop new pore structure and surface area of the zeolite molecular sieves to increase the adsorption capacity. These improvements have made them more versatile and suitable for use in industries since they are cheaper and more effective.

Future Trends

The future of zeolite molecular sieves appears to be bright with possibilities of growth in the existing markets and penetration into new ones. The need for cleaner technologies and environmentally friendly industrial processes is expected to drive the demand for better adsorbent solutions such as zeolite molecular sieves. They are versatile and efficient to meet these changing needs especially in industries that embrace environmental conservation and energy use.

In conclusion, zeolite molecular sieves are one of the most important types of adsorbents used in the contemporary industry. Due to their selectivity, they can be used selectively and effectively to remove specific impurities, which makes them very important in increasing product quality and process effectiveness in numerous industries. As industries look for better and more efficient solutions, the contribution of zeolite molecular sieves is expected to grow even more, thus pushing the development of adsorbent technology forward.