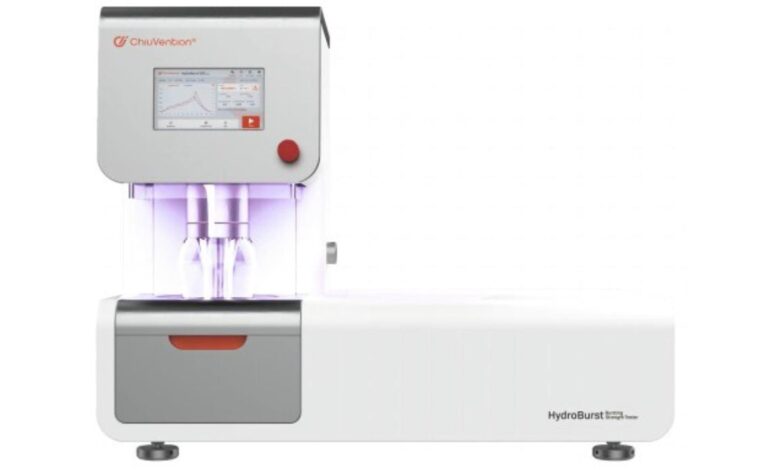

The Role of the HydroBurst Bursting Strength Tester in Ensuring Textile Durability

In the world of textiles, maintaining fabric quality is essential for various applications, from clothing to industrial materials. One of the most reliable ways to measure fabric performance is through the bursting strength test. The HydroBurst Bursting Strength Tester is an advanced tool that provides accurate and efficient testing, ensuring that textiles meet the necessary durability standards.

What is Bursting Strength?

At its core, bursting strength measures a fabric’s ability to withstand pressure before it ruptures. This is especially important for materials that face significant stress in everyday use, such as medical textiles, upholstery, and workwear. Understanding what is bursting strength allows manufacturers to produce fabrics that are not only strong but also safe and durable for their intended purposes.

Bursting Strength Test Method

The bursting strength test method is a procedure that involves applying pressure to a piece of fabric until it bursts. This test determines how well a material can resist stress and pressure in real-world scenarios. The HydroBurst Bursting Strength Tester automates this process, offering precise and consistent results, making it an indispensable tool for textile professionals.

Bursting Strength in Textile Applications

The significance of bursting strength in textile manufacturing cannot be overlooked. From clothing manufacturers ensuring their products can withstand wear and tear to industrial fabric producers needing materials to endure extreme conditions, bursting strength plays a critical role. Fabrics that fail this test may not hold up under strain, leading to product failure, costly recalls, or even safety hazards. The HydroBurst Bursting Strength Tester helps mitigate these risks by providing reliable assessments of fabric strength.

Calculating the Bursting Strength Formula

The bursting strength formula calculates the pressure required to rupture a fabric, usually expressed in terms of pressure over a given surface area. By accurately determining this value, manufacturers can tailor their production processes to create textiles that are robust and suitable for various applications. Using the HydroBurst Bursting Strength Tester, textile engineers can easily apply this formula to get precise data on fabric durability.

Why Choose the HydroBurst Bursting Strength Tester?

The HydroBurst Bursting Strength Tester stands out due to its:

- Accuracy and Consistency: Provides reliable data, reducing human error and ensuring fabrics meet industry standards.

- Versatility: Suitable for testing a wide range of textiles, from heavy-duty industrial fabrics to lightweight apparel materials.

- Ease of Use: Designed with user-friendly controls for seamless operation in any textile facility.

Conclusion

The HydroBurst Bursting Strength Tester plays an integral role in ensuring fabric quality and durability across various industries. By understanding the bursting strength test method and applying the bursting strength formula, manufacturers can produce textiles that meet the highest standards of performance and safety. For anyone in the textile industry, investing in a high-quality testing tool like the HydroBurst Bursting Strength Tester is essential for achieving reliable and long-lasting results.